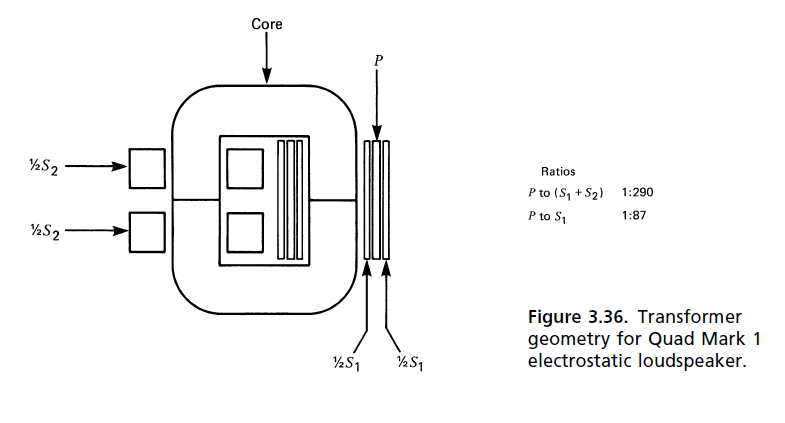

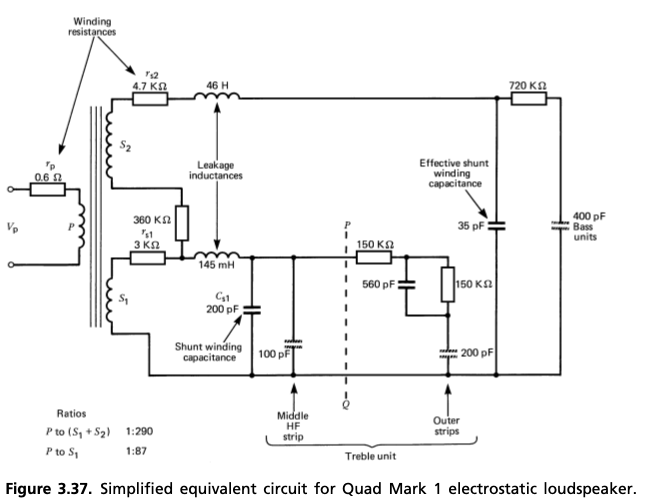

Audio input transformer is a step-up kind with ratios of 90 for treble and 270 for bass (quote from quadesl.com). Sheldon Stokes says 96/270. diyAudio/bolserst says 87/290. diyAudio/Imazed says 96/289 … But this is based on voltage or turns measurement ? Probably first choice: voltage measurement.

You can read 55/110 here. This ratio is for windings themselves, and overall this makes 2*55 and (110+2*55+110): “110 / 330”. It may be related to turns ratio this time.

Maximum voltage at treble side should remain far below 3kV, which can be forced by an optional clipping board that clamps at 2200V. This 3kV corresponds to about 33Vp at input side.

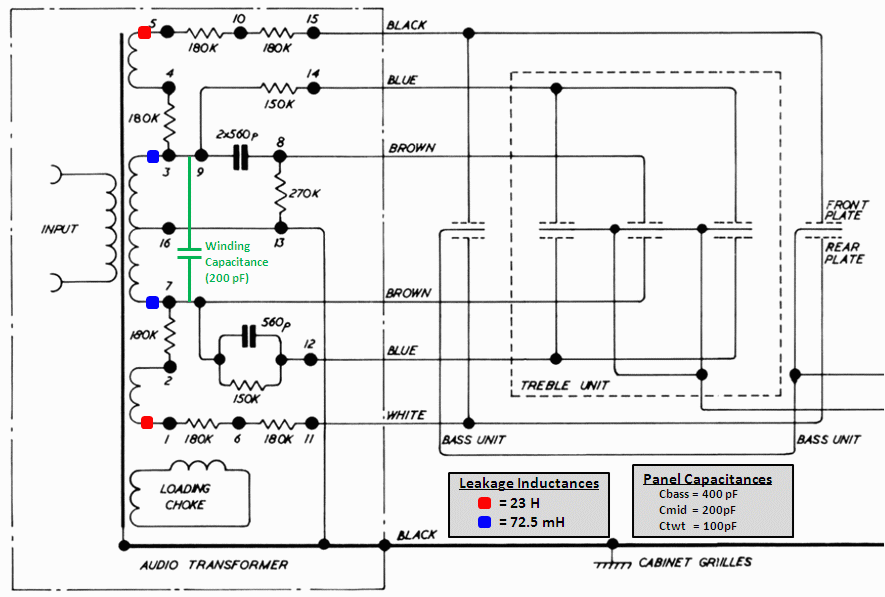

Components used inside audio transformer do have to support up to 6kV. But this happens only with high power amplifiers such as Quad 303 (2x45W). With 5W, voltage inside audio transformer will stay below 100V. But who wants to use as little power as 5W with a low sensitivity speaker? Therefore, use high voltage components only! quadesl.org specifies 10kV for resistors and 4 to 6 kV for capacitors. Considering schematic (3 resistors inserted in serie in the bass line), VR37 are probably good enough. VR68 will be overkill but are still good choice since same size as original components. Besides, 1W vs 1/2W.

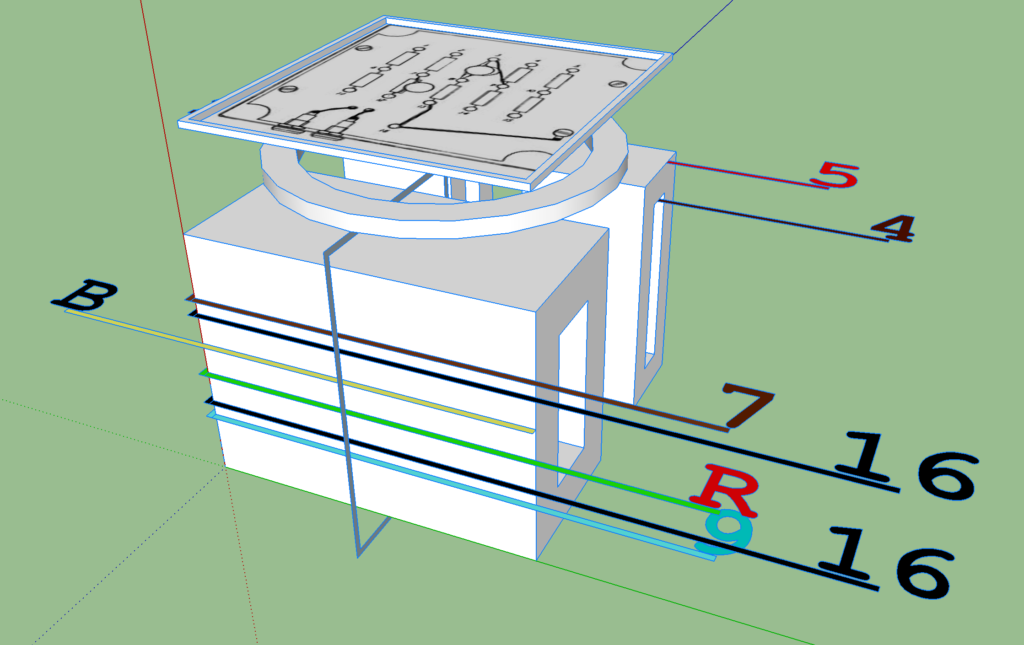

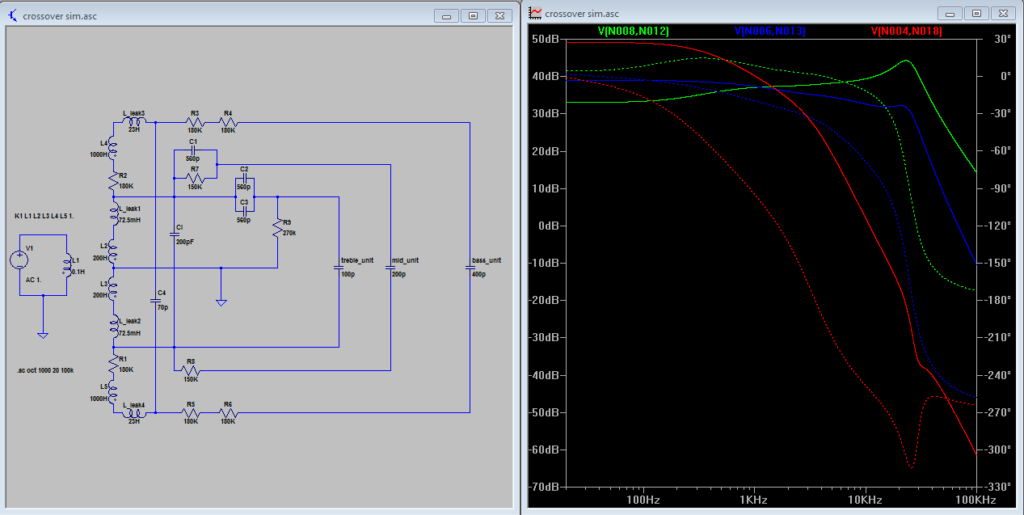

Model

An interesting discussion occured on diyAudio, here. See some extracts from contributor ‘bolserst‘ below:

For a complete understanding of the ESL-57 crossover as well as its acoustic design I would highly recommend reading the description by Peter Baxandall on pages 169 – 179 of “Loudspeaker and Headphone Handbook”, J. Borwick, Ed. |

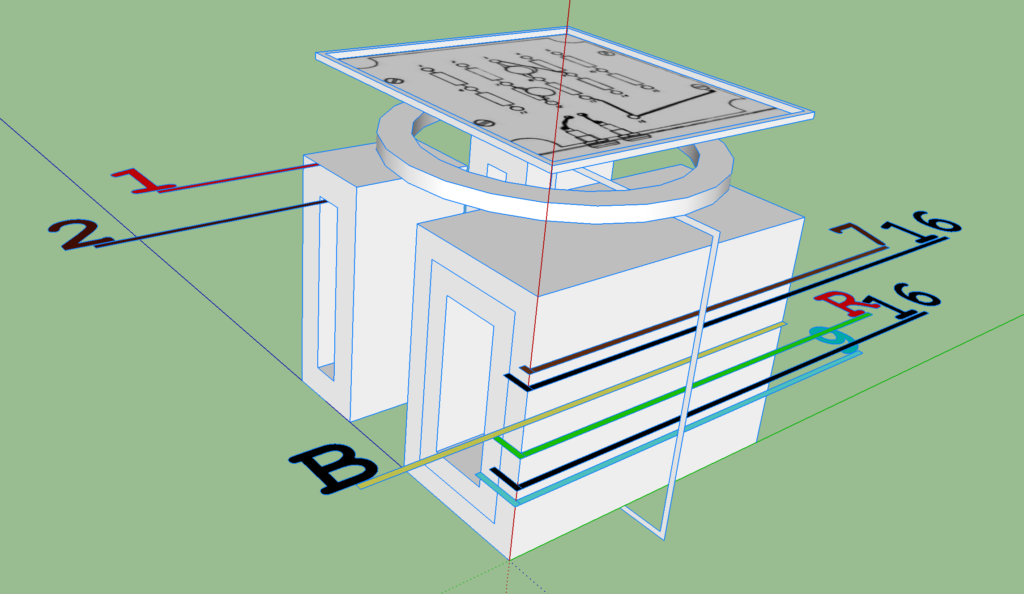

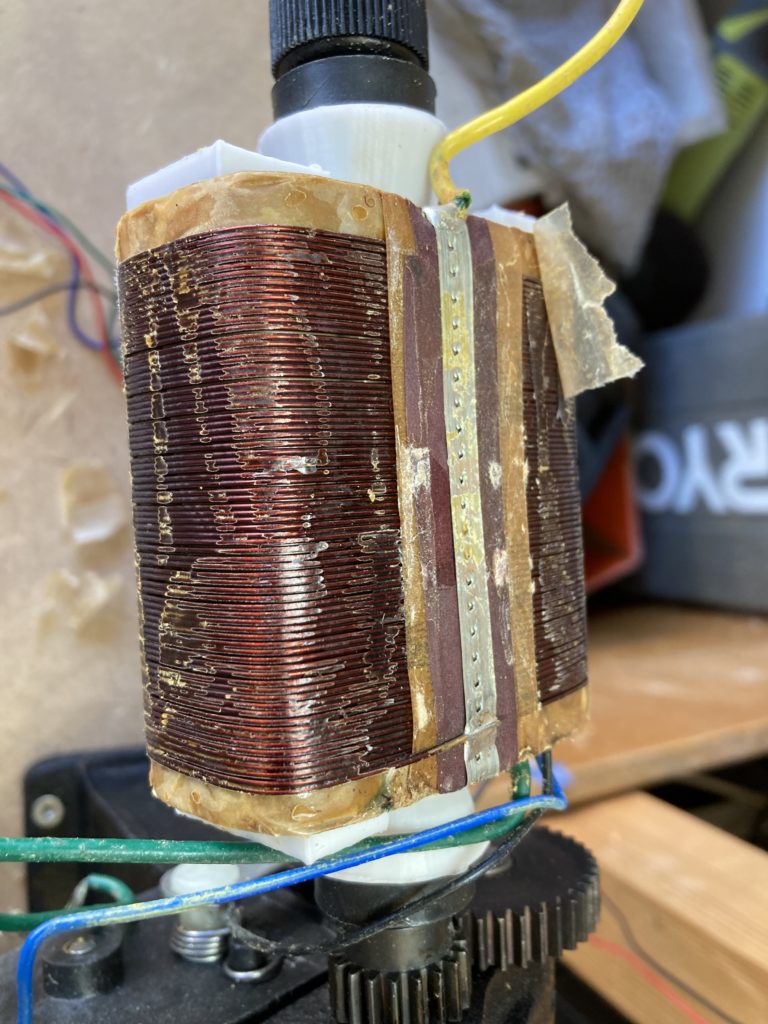

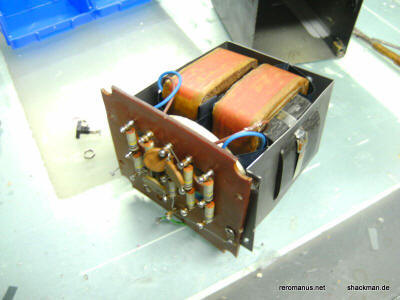

As you can see on pictures above:

- outer wires of the 2 small coils connect to outer terminals (1 and 5 for serie 2)

- inner wires of the 2 small coils connect to inner terminals (2 and 4 for serie 2)

- small coils are on the top side (near plots 1 .. 5) and are a priori identical

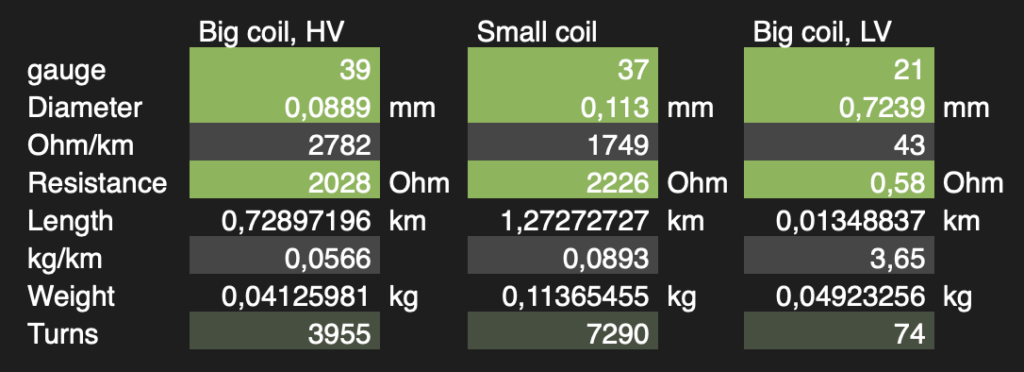

How many turns ? I got this from one source:

- Small coils are expected 7850 turns gauge #39 (0.0889mm) !! not what I measured, see below !!

- Audio inputs (B/R) make 74 turns, gauge #21 (0.7239mm)

- Last, big coils, 2 times 3926 turns gauge #39, turns ratio 53

On my side, I measured for small coils:

- for one transfo, 180 turns per layer (width = 1 inch, thus diameter<0.141mm), and computed 1715 Ω/km: gauge #37 (0.113mm)

- for another transfo, I got this on just one layer (slightly less accurate): 34.7m for layer #4 and 64.7Ohm and 3.1g -> 1.86Ohm/m, 89g/km: definitely gauge #37

- for one coil, 41 layers, first and last being partly filled, around 180 turns/layer, 180*40.5=7290 turns in total

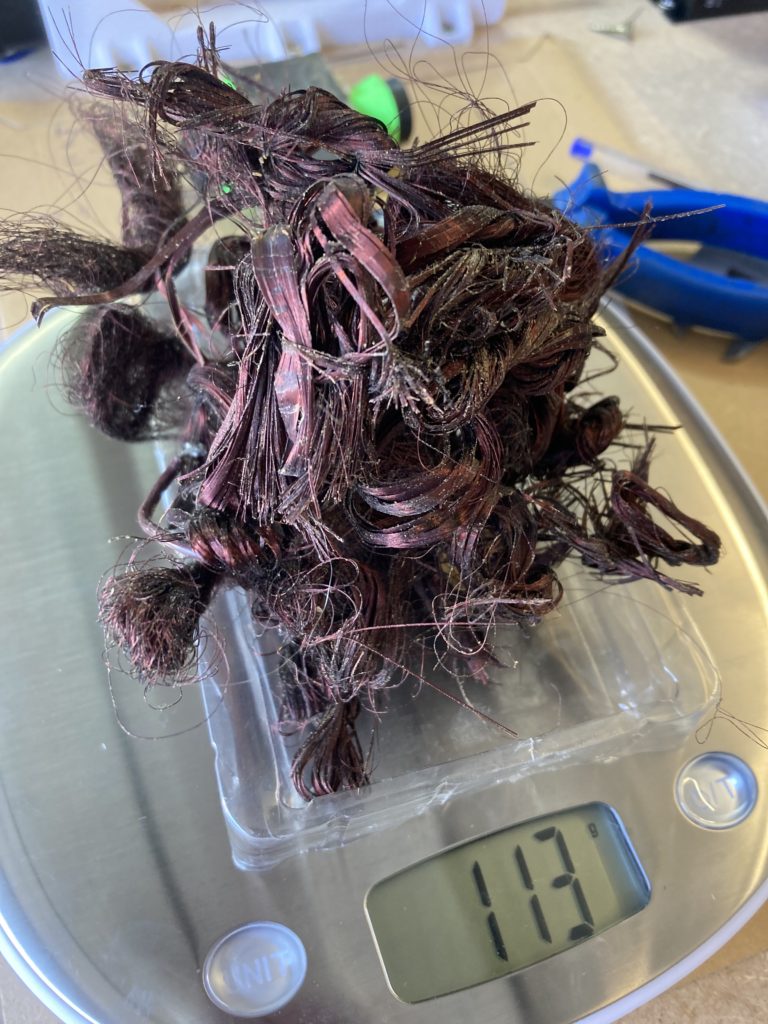

- for another coil, 40 layers only, around 182.5 turns/layer, 128 only for first and last, 7211 turns in total, 113g of wire

- this makes turns ratio 97.5 .. 98.5, resistance close to 2.2 kΩ. Obviously only total number of turns was monitored

For big coils, and each instance of high voltage wiring:

- 8 layers, first and last being half filled

- 565 turns per complete layer: about 3955 turns in total (turns ratio 53)

- target is 1.93/1.73 kΩ (note that inner and outer wiring have same # of turns but not same radius thus not the same resistance)

For big coils, low voltage wiring:

- I confirm gauge 21, 74 turns, 0.58 Ohm, 13.25m, 1 layer only

Additional notes:

- 1st layer is half-filled, and starts towards left

- seen from connection wires, small and big coils are NOT wired in the same sense: anti-clockwise for small ones

- 3.5 turns of paper is used between layers for insulation of big coils, only 1.5 turns for small coils

- big coils have additional external insulation layers (4m30!), less for small coils (1m)

- not all coils measure the same !

My summary:

- apply turns ratio of 53/98 (this makes a voltage ratio of “106/302” before applying yield and loss, to obtain hopefully the famous “90/290” after)

- small coils: layers of 180 .. 185 turns, gauge 37, 40 .. 41 layers, 7250 turns (first and last layers filled at 75%), set winding tool with a spacing for a gauge 2 steps below (25.4mm/180). 1.5 turn of insulation between each layer (1.5 inch), 5 turns for final insulation

- big coils, HV: layers of 565 turns, gauge 39, 8 layers, 3950 turns (first and last half-filled)

- big coils, LV: 1 layer of 74 turns gauge 21

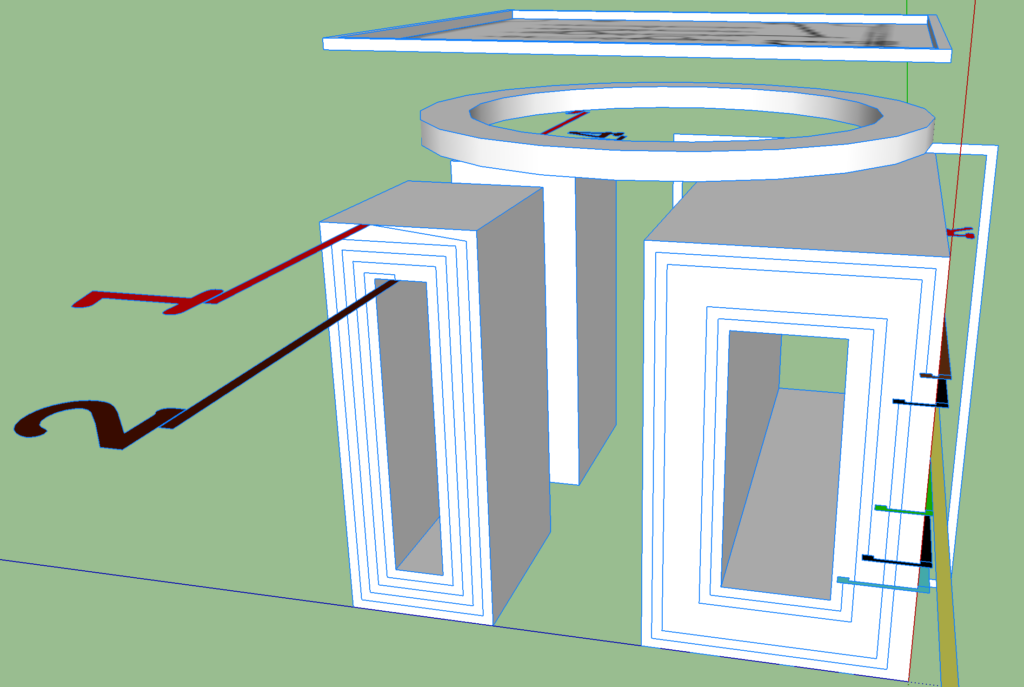

- once completed with external insulation, small coils should mesure less than 42x76mm (paper core is 21x56mm, height 36mm, external side). One turn will vary between 19.3cm and 15.4cm (avg 17.35cm thus roughly 1265m in total and 2.2kOhm)

- for big coils, height of paper core is 74mm (insulation can be 2×1.5 inches wide)

- the 2 small coils are identical. Take care to wire direction: see picture

Impedance computation:

- http://www.dicks-website.eu/coilcalculator/

- https://www.eeweb.com/tools/rectangle-loop-inductance/

- https://www.diyaudio.com/community/threads/explaining-the-quad-esl-57-crossover.224615/

- big coil, LV, 100mH (Al value = 18260nH/N^2)

- big coil, HV, 300H

- small coil, 1000H

Here is a code to reproduce measurements above, with figures from Baxandall:

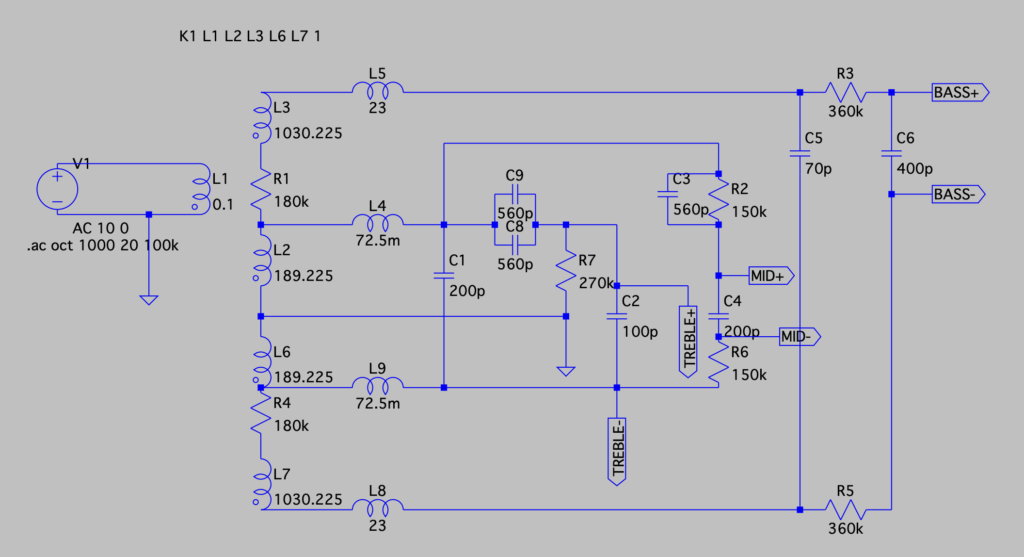

Version 4

SHEET 1 1176 760

WIRE 144 -32 0 -32

WIRE 848 -32 224 -32

WIRE 880 -32 848 -32

WIRE 992 -32 960 -32

WIRE 1056 -32 992 -32

WIRE 848 32 848 -32

WIRE 992 32 992 -32

WIRE 720 48 288 48

WIRE -96 80 -320 80

WIRE 0 80 0 48

WIRE 720 96 720 48

WIRE 720 96 640 96

WIRE 992 128 992 96

WIRE 1056 128 992 128

WIRE -176 160 -320 160

WIRE -96 160 -176 160

WIRE 0 176 0 160

WIRE 144 176 0 176

WIRE 288 176 288 48

WIRE 288 176 224 176

WIRE 368 176 368 128

WIRE 368 176 288 176

WIRE 432 176 432 128

WIRE 480 176 432 176

WIRE 560 176 480 176

WIRE 640 176 640 160

WIRE 720 176 640 176

WIRE 0 192 0 176

WIRE 368 208 368 176

WIRE 432 208 432 176

WIRE 480 208 480 176

WIRE 288 224 288 176

WIRE 720 256 720 176

WIRE 768 256 720 256

WIRE 560 272 560 176

WIRE 672 272 560 272

WIRE -176 288 -176 160

WIRE 560 288 560 272

WIRE 720 288 720 256

WIRE 672 304 672 272

WIRE 0 320 0 272

WIRE 480 320 480 288

WIRE 480 320 0 320

WIRE 0 352 0 320

WIRE 816 352 720 352

WIRE 480 400 480 320

WIRE 144 432 0 432

WIRE 288 432 288 288

WIRE 288 432 224 432

WIRE 560 432 560 352

WIRE 560 432 288 432

WIRE 720 432 560 432

WIRE 560 480 560 432

WIRE 0 544 0 512

WIRE 144 624 0 624

WIRE 848 624 848 96

WIRE 848 624 224 624

WIRE 880 624 848 624

WIRE 992 624 992 128

WIRE 992 624 960 624

FLAG -176 288 0

FLAG 1056 -32 BASS+

IOPIN 1056 -32 Out

FLAG 480 400 0

FLAG 672 304 TREBLE+

IOPIN 672 304 Out

FLAG 768 256 MID+

IOPIN 768 256 Out

FLAG 1056 128 BASS-

IOPIN 1056 128 Out

FLAG 560 480 TREBLE-

IOPIN 560 480 Out

FLAG 816 352 MID-

IOPIN 816 352 Out

SYMBOL ind2 -112 64 R0

SYMATTR InstName L1

SYMATTR Value 0.1

SYMATTR Type ind

SYMATTR SpiceLine Rser=0.6

SYMBOL ind2 -16 176 R0

SYMATTR InstName L2

SYMATTR Value 189.225

SYMATTR Type ind

SYMATTR SpiceLine Rser=1500

SYMBOL ind2 -16 -48 R0

SYMATTR InstName L3

SYMATTR Value 1030.225

SYMATTR Type ind

SYMATTR SpiceLine Rser=2350

SYMBOL res -16 64 R0

SYMATTR InstName R1

SYMATTR Value 180k

SYMBOL ind 128 192 R270

WINDOW 0 32 56 VTop 2

WINDOW 3 5 56 VBottom 2

SYMATTR InstName L4

SYMATTR Value 72.5m

SYMBOL ind 128 -16 R270

WINDOW 0 32 56 VTop 2

WINDOW 3 5 56 VBottom 2

SYMATTR InstName L5

SYMATTR Value 23

SYMBOL cap 272 224 R0

SYMATTR InstName C1

SYMATTR Value 200p

SYMBOL cap 544 288 R0

SYMATTR InstName C2

SYMATTR Value 100p

SYMBOL cap 624 96 R0

SYMATTR InstName C3

SYMATTR Value 560p

SYMBOL cap 832 32 R0

SYMATTR InstName C5

SYMATTR Value 70p

SYMBOL cap 976 32 R0

SYMATTR InstName C6

SYMATTR Value 400p

SYMBOL res 704 80 R0

SYMATTR InstName R2

SYMATTR Value 150k

SYMBOL res 976 -48 R90

WINDOW 0 0 56 VBottom 2

WINDOW 3 32 56 VTop 2

SYMATTR InstName R3

SYMATTR Value 360k

SYMBOL voltage -320 64 R0

WINDOW 3 24 96 Invisible 2

WINDOW 123 24 118 Left 2

SYMATTR InstName V1

SYMATTR Value SINE()

SYMATTR Value2 AC 10 0

SYMBOL ind2 -16 336 R0

SYMATTR InstName L6

SYMATTR Value 189.225

SYMATTR Type ind

SYMATTR SpiceLine Rser=1500

SYMBOL res -16 416 R0

SYMATTR InstName R4

SYMATTR Value 180k

SYMBOL ind2 -16 528 R0

SYMATTR InstName L7

SYMATTR Value 1030.225

SYMATTR Type ind

SYMATTR SpiceLine Rser=2350

SYMBOL ind 128 640 R270

WINDOW 0 32 56 VTop 2

WINDOW 3 5 56 VBottom 2

SYMATTR InstName L8

SYMATTR Value 23

SYMBOL cap 704 288 R0

SYMATTR InstName C4

SYMATTR Value 200p

SYMBOL ind 128 448 R270

WINDOW 0 32 56 VTop 2

WINDOW 3 5 56 VBottom 2

SYMATTR InstName L9

SYMATTR Value 72.5m

SYMBOL res 976 608 R90

WINDOW 0 0 56 VBottom 2

WINDOW 3 32 56 VTop 2

SYMATTR InstName R5

SYMATTR Value 360k

SYMBOL res 704 336 R0

SYMATTR InstName R6

SYMATTR Value 150k

SYMBOL res 464 192 R0

SYMATTR InstName R7

SYMATTR Value 270k

SYMBOL cap 432 192 R90

WINDOW 0 0 32 VBottom 2

WINDOW 3 32 32 VTop 2

SYMATTR InstName C8

SYMATTR Value 560p

SYMBOL cap 432 112 R90

WINDOW 0 0 32 VBottom 2

WINDOW 3 32 32 VTop 2

SYMATTR InstName C9

SYMATTR Value 560p

TEXT -128 -120 Left 2 !K1 L1 L2 L3 L6 L7 1

TEXT -368 208 Left 2 !.ac oct 1000 20 100k

Pictures imported from other sites:

![]()