Either use a tension scale (“Force Gauge Spring Dynamometer”) or make your own jig, as Quad did.

For the latter solution, you will need 28 weights of 1.5 lbs for the bass, and 28 weights of 3 lbs for the treble. From a practical point of view, 2 times 28 weights of 1.5 lbs is preferable. Yet, I read this:

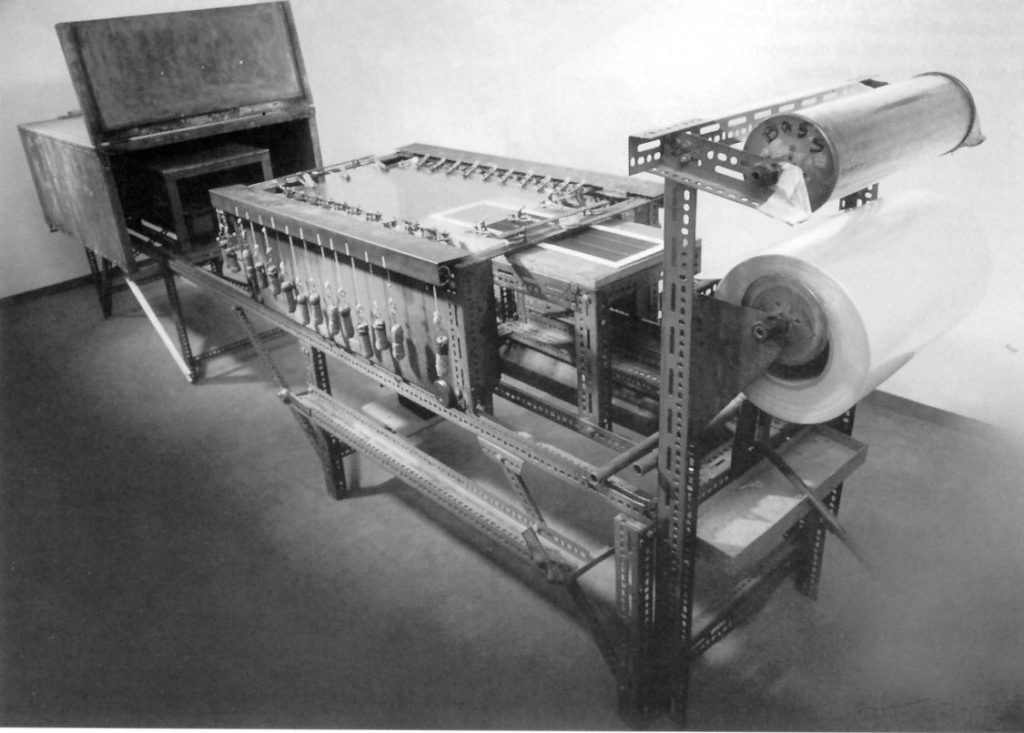

“The original Quad stretching jig uses steel weights which total to 45kg for the mid/high-panel and some 60 kg for the bass-panels. I have seen the original jig, which is now in Germany, and if I recollect correctly they have 30 weights. So, each weight is about 1,5kg for the mid/high and 2kg for the bass. If you apply these values you will be very close to the original way Quad is tensioning their panels. This is only valid if the tensioned area is in the vicinity of some 40 by 80 cm. The panel itself is apparently smaller. So if you intend to refurbish Quad panels or build new ones with the same dimensions this should put you very close to Quads specifications. ” (https://www.diyaudio.com/community/threads/quad-esl-57-question.112142/)

So, what to choose? I’m pretty happy with 28*3lbs for the treble. But 28*1.5lbs for the bass seems not enough. Let’s think twice:

- resonant frequency of cells in free air are expected to be 70 and 260Hz (Baxandall)

- mylar oscillates at a frequency = k/Length*sqrt(Force/Density), if using simple string model

- 70/260=1/(93.15/44.50)*sqrt(ForceRatio/DensityRatio), with DensityRatio=2 (12um vs 6um)

- ForceRatio=0.63 : if applying 28*3lbs on treble, I should apply 28*1.9lbs on bass, or 35*1.5lbs on bass, or even more if considering difference of perimeter of the area on which the weights apply: 39*1.5lbs

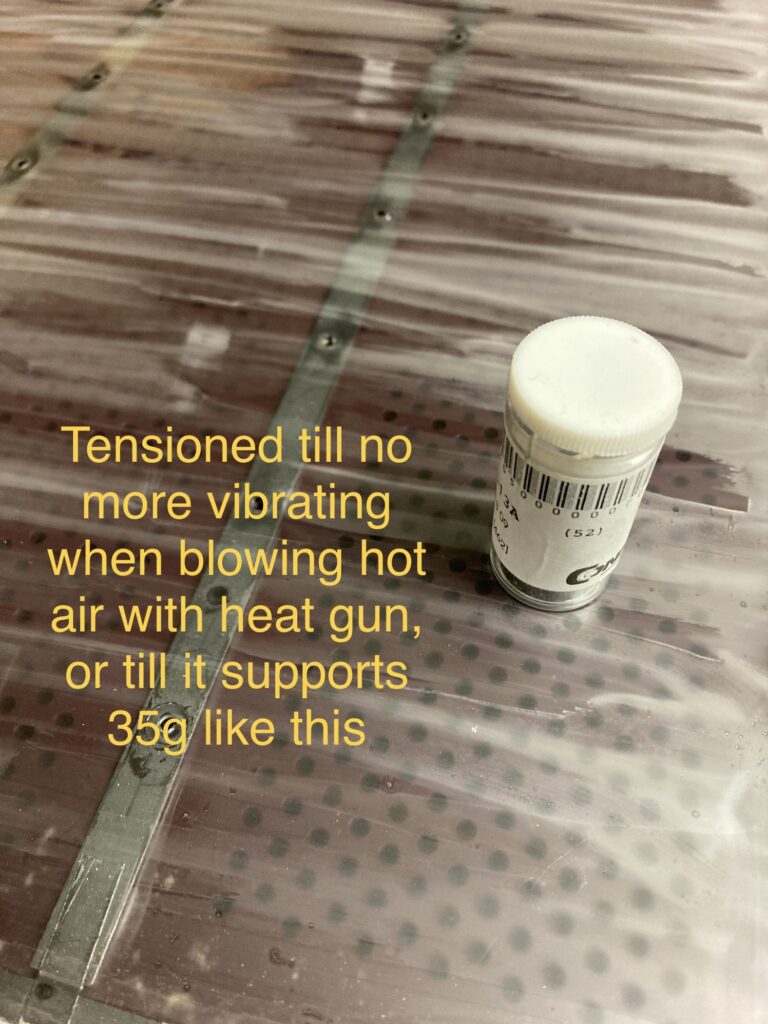

- Note that is DensityRatio is now considered as 1 and not 2, because the mass to consider is the mass of the air, not the film itself, we find 20*1.5lbs ! Now that you have a max and a min, make up your own mind ! I tried 52 and this is far too high … with mylar

My current choice:

- Mylar 6um, 28*3lbs for treble

- Mylar 12um, 34*1.5lbs for bass (I tried regular PVC 12um, 42*1.5lbs but saturates with low frequencies and tricky to stretch since too fragile)

For bass film, use preferably 12 um PVDC (see Baxandall why: young’s module), alternative being 12 um PE (aka Mylar, Melinex, Hostaphan,…). Yet, I know other people prefer Mylar 6 or 3 um here: this can be tried, but I can’t say how much you have to stretch it.

For treble film, use 6 um Mylar. Due to higher strength applied, annealing will be suggested for this one.

And for dust covers, use same film as for diaphragms.

And how to proceed without all this stuff ? You can try the heat gun at 100•C:

With mylar, it’s important to pre-tension the best you can to keep some margin for heat shrinking.

![]()